Ruth Murray-Webster and Peter Simon

Earned Value Management (EVM) has existed in a documented form since the 1960s although the underlying question behind the approach (what am I getting for the money I have spent) has obviously been around for a lot longer! As a project management technique we find that only a few organisations or business sectors apply it fully; for example defence (it is mandated by both the US and UK’s defence procurement bodies), rail transportation and civil/mechanical construction e.g. utilities.

Earned Value Management (EVM) has existed in a documented form since the 1960s although the underlying question behind the approach (what am I getting for the money I have spent) has obviously been around for a lot longer! As a project management technique we find that only a few organisations or business sectors apply it fully; for example defence (it is mandated by both the US and UK’s defence procurement bodies), rail transportation and civil/mechanical construction e.g. utilities.

However to many of those involved in project management it is still largely a mystery confined only to the realm of a topic needed to be learned in order to pass APM’s APMP or PMI’s PMP® examination; but once learned, and having successfully passed the exam, instantly forgotten. We wonder why this is - as surely the underlying principle of EVM is applicable to all projects?

According to an early publication from the APM’s Earned Value Specific Interest Group (EV SIG) “Earned Value Management is the measurement and monitoring of project progress in terms of cost, time and technical/physical achievement against a defined scope of work”. The EV SIG imply that all you need to do to carry out EVM is follow these 10 easy steps (note we have added some extra, fundamentally important words to the steps which are highlighted):

- Develop a Work Breakdown Structure (WBS) for your project that covers its entire, agreed scope.

- Develop an Organisational Breakdown Structure (OBS) that aligns to the WBS that ensures responsibility for work accomplished.

- Distribute the project’s total budget (or resource effort) across elements of the WBS (at a consistent level in the breakdown structure).

- Schedule the work contained in the WBS and thus spread the budget over the project’s schedule/duration.

- Identify a method to measure achievement.

- Baseline the plan.

- Record all costs (actual costs plus accruals or effort expended).

- Collect and analyse performance data (using the method that should have been identifi ed in 5 above!).

- Produce forecasts for remaining work.

- Incorporate authorised changes in a timely manner.

Simple isn’t it?! So where does it start to become difficult? We work with many organisations that understand the validity of EVM in principle but struggle to make it work, those trying gradually falling by the wayside as they attempt to get past step 10 to reap the benefits of EVM. Those of you reading this and thinking about implementing EVM might want to see how far you can get on your route to step 10 and beyond. Let’s look at each of the 10 steps one by one and see where the difficulties lie.

-

Develop a WBS. Easier said than done; as we know not all projects have a WBS or any other means of visualising the agreed scope of the project. Note agreed scope, i.e. a scope that is signed off by all relevant stakeholders that will only be changed via a formal change control process. Without this step 3 will be impossible.

-

Develop an OBS. Whether you call it an OBS or you use something like a RACI Chart/Responsibility Assignment Matrix what is needed is clear ownership of work packages/work elements. This is essential for tracking progress and forecasting remaining durations, costs or resources. To do this requires unambiguous accountability for achievement of the planned work.

-

Based on the agreed scope the project’s budget (or resource effort) needs to be distributed across elements of the WBS such that…

-

…it can be phased over time (via the project’s schedule) in order to produce a planned expenditure curve. To do this you need a schedule that encompasses the total agreed scope and a budget (or resource effort) that can be cast against that schedule. You also need a schedule that is granular enough to allow appropriate performance measurement (see steps 5 and 8).

-

Be able to measure achievement or physical progress against the plan. As many of you will know this can be difficult. Some EVM practitioners suggest using a 0 or 100 method i.e. project activities are either 0% or 100% physically complete, and nothingin between. Others like 0 - 50 -100 where 50% is allocated for all ‘in flight’ activities. To do this effectively you need relatively small activities that are not planned to take place over more than two reporting periods (the PMI 80 hour rule). If you have longer activities then a more precise method of measuring achievement is needed. This is easy in some industries where deliverables such as length of pipe installed or bricks laid can be counted but when writing IT code or preparing documentation it is more difficult. We have seen many mechanisms for doing this but all have been tailored specifi cally to the circumstances in which they are to be used.

-

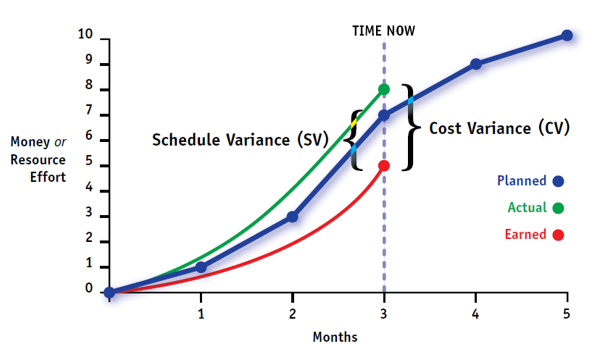

Baseline the plan. If you’ve got this far then this could be the easiest step but remember once baselined you CANNOT change the plan without consent - see step 10. The baseline (or re-baseline) will determine the Planned Value (PV) for the project at any point in time and is where the typical ‘S’ curve for the project is generated.

-

Record actual costs (or actual effort expended) - preferably at work package or activity level. You cannot rely on the company’s general ledger system for this as it will probably lag significantly behind real time. This is traditionally the domain of the cost engineer or project accountant who has the job of providing timely ‘actual’ information that takes into account all known accruals. Without such a resource this will prove much more difficult. In EVM terms this allows you to determine Actual Costs (AC).

-

Collect and analyse performance data. Based on the mechanism determined in step 5 above, physical progress can be used to determined the project’s Earned Value (EV). These data must align to the same cut-off date as the actual information reported in step 7.

-

Produce forecasts for remaining work. Using the three EVM ingredients of Planned Value (PV), Actual Costs (AC) and Earned Value (EV), and a multitude of formulae, forecast data can be prepared. Note the old and recurring adage of ‘garbage in garbage out’ haunts this apparently simple step. If you have an incomplete or not agreed scope, a poor estimate, a badly constructed or unrealistic schedule, inaccurate actual costs, optimistic (or pessimistic) progress measurement then any or all forecast data will be worthless.

-

Incorporate changes in a timely manner. It is important that the baseline should not change ‘willy-nilly’ but it should reflect the current approved scope; if not any forecast data will again be meaningless. To do this requires both an efficient and effective change control process that allows approved changes to be instantly recognised in a revised budget, resource effort requirements and schedule. If the project changes without the use of formal change control then anarchy will take over and EVM as a monitoring and control technique will be useless.

And that’s all there is to it!

We were prompted to write this article by an organisation that we work with that is about to embark on a full implementation of EVM on all of its major projects. Even though the benefit to be gained from its implementation is obvious to many of those involved in delivering these projects some are still concerned if the effort required will be actually worthwhile. What seems strange to us is that in asking that question, it must be seen as acceptable to some people that projects proceed without clear agreed scope, roles and responsibilities assigned, schedule developed, progress tracked and change controlled.

- © Lucidus Consulting

- www.lucidusconsulting.com